When planning an elevator installation, one of the key decisions builders face is selecting the right suspension system. Traditional wire ropes have been the industry standard for decades, but advancements in technology have introduced steel belts, offering a modern alternative. The question is: Which option is safer and more reliable? Understanding the differences between these two systems is essential to making an informed choice that ensures long-term performance, efficiency, and safety.

In this article, we will explore the key differences between steel belts and wire ropes, assess their safety and durability, and provide professional recommendations to help builders select the best option for their projects.

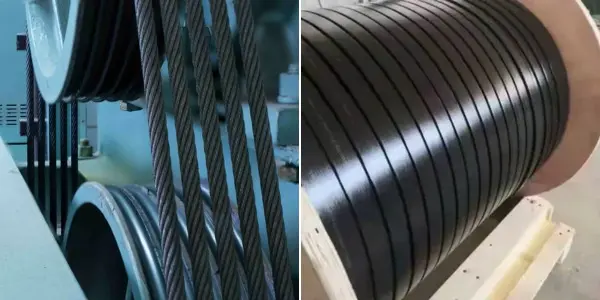

The suspension system is a critical component of an elevator, responsible for supporting and moving the elevator car. Traditionally, elevators have relied on steel wire ropes, which consist of multiple strands of steel wires twisted together for strength and flexibility.

On the other hand, steel belts are a more recent innovation, featuring a flat design reinforced with high-strength steel cords encased in a polymer coating. This structure eliminates the need for lubrication and allows for smoother operation.

Each system has its strengths, and the best choice depends on various factors, including building height, space availability, maintenance considerations, and long-term operational costs.

Factor | Steel Belts | Wire Ropes |

Safety | Higher safety margin due to flexible, non-corrosive coating and precise traction control. | Reliable but requires regular inspection to prevent wear and tear. |

Durability | Long lifespan with minimal wear and no lubrication needs. | Shorter lifespan due to friction and the need for regular lubrication. |

Load capacity | Supports high-speed and heavy-load applications. | Suitable for standard passenger and freight elevators. |

Maintenance | Requires minimal maintenance; no lubrication needed. | Needs frequent lubrication and tension adjustments. |

Smooth operation | Quieter and smoother ride due to polymer coating. | Can become noisy over time as cables wear. |

Corrosion resistance | Polymer coating protects against corrosion and environmental damage. | Metal wires are prone to rust and wear. |

Steel belts offer superior durability, lower maintenance, and enhanced safety features, making them a strong contender for modern elevator installations.

When deciding between steel belts and wire ropes, it is essential to look beyond the initial cost and evaluate long-term value.

For builders looking at total lifecycle costs, steel belts often prove to be the more economical choice despite the higher initial purchase price.

Selecting between steel belts and wire ropes depends on several operational, economic, and maintenance factors. Below is a professional selection guide to help elevator maintenance personnel and building owners make an informed decision.

Factor | Steel Belts | Wire Ropes |

Durability & lifespan | Longer lifespan due to reduced wear and no lubrication needs. | Shorter lifespan as wires fray and require regular tension adjustments. |

Maintenance requirements | Lower maintenance; no lubrication required but periodic inspection is needed. | Requires regular lubrication and tension monitoring to prevent fraying. |

Load capacity | Suitable for high-speed and high-capacity elevators. | Reliable for standard passenger and freight elevators. |

Energy efficiency | Higher efficiency due to lighter weight and reduced traction loss. | Less efficient due to heavier structure and higher rolling resistance. |

Space efficiency | More compact design allows for smaller machine rooms and sheaves. | Requires larger machine room due to thicker cables and larger sheaves. |

Operational smoothness & noise | Quieter and smoother operation due to non-metallic surface. | Can generate more noise and vibration over time. |

Cost considerations | Higher initial investment but lower lifetime maintenance costs. | Lower initial cost but higher long-term maintenance expenses. |

Choosing between steel belts and wire ropes is not just about comparing two technologies—it’s about finding the right solution for your building’s needs.

At POTENSI, we supply high-quality elevator parts, including steel belts and premium wire ropes from leading manufacturers. No matter your project’s requirements, we can help you select the best suspension system for your elevator installation.

Looking for high-quality elevator steel belts or wire ropes for your next project? POTENSI provides top-tier elevator parts designed for durability and performance. Contact us today to find the right solution for your building!

① Get 10% off on your first order.

② Get latest news about our promotion products.

③ Get our sales specialist VIP service 24/7.

④ Get access to our credit payment time.

WhatsApp us