Elevator wire ropes are the lifeblood of safe and efficient elevator operations. For maintenance personnel, safeguarding their integrity is of utmost importance. Over time, mechanical stress, environmental exposure, and improper maintenance can gradually erode their quality. Neglecting these signs not only results in costly repairs but also poses serious safety risks.

In this comprehensive guide, we will explore the critical indicators of wire rope wear, effective inspection methods, and best practices for maintenance and replacement. By following these steps, we can ensure that elevators operate at their best, keeping passengers safe.

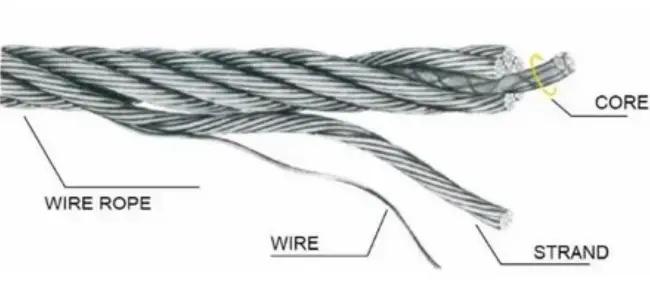

An elevator wire rope is a high – strength steel rope engineered to support and move elevator cabins. It is composed of multiple strands of steel wires twisted around a core, combining flexibility, durability, and high load – bearing capacity. This unique construction allows it to withstand the constant stress of elevator operations.

Elevator wire ropes come in a variety of configurations:

Typically made of high-carbon steel for strength and wear resistance, some wire ropes are coated with synthetic materials or have special lubricants to enhance their lifespan.

A worn – out elevator wire rope is a ticking time bomb. It jeopardizes passenger safety and can lead to unexpected breakdowns. The risks are significant:

Regular inspections and proactive maintenance are not just about safety; they also make good financial sense. By detecting issues early, we can prevent premature failures, reducing repair costs and minimizing elevator downtime. Investing in early detection methods helps avoid costly replacements and potential liability issues.

Understanding the reasons behind wire rope degradation is the first step in prevention. The most common causes are:

Each wire rope has specific tolerance limits set by the manufacturer. If the wear exceeds these limits, replacement is essential to maintain safe operation.

Replacing a wire rope before failure is a smart investment. It prevents costly elevator downtime and safety hazards. Proactively scheduling replacements is far more cost-effective than dealing with emergency failures.

A commercial building in Dubai was plagued by frequent elevator breakdowns due to premature wire rope failure. After implementing monthly wear assessments and switching to a high – durability wire rope, downtime decreased by 40%, resulting in significant savings in repair costs.

Visible broken wires, flattening, corrosion, and diameter reduction are key indicators.

Daily for visual checks, monthly for detailed inspections, and annually for professional testing.

Proper lubrication, tension adjustment, and avoiding overloading help extend durability.

Regular inspection and timely maintenance of elevator wire ropes are the cornerstones of ensuring safety and operational efficiency. By following structured inspection methods, using advanced testing techniques, and adhering to industry standards, we can extend wire rope lifespan and reduce unexpected failures.

For premium-quality elevator wire ropes and expert solutions, explore the POTENSI range of durable and high-performance products. Contact us today to find the best solutions for your maintenance needs!

① Get 10% off on your first order.

② Get latest news about our promotion products.

③ Get our sales specialist VIP service 24/7.

④ Get access to our credit payment time.

WhatsApp us