The elevator wire rope is one of the most critical components of an elevator system. It plays a vital role in supporting the car and counterweight while providing the traction needed for smooth and safe operation. Yet, many people overlook how important proper rope configuration is for performance and durability.

A well-designed rope configuration ensures the elevator operates efficiently, reduces wear on components, and enhances safety. By understanding the different roping setups, you can make informed decisions when maintaining or upgrading your elevator system. This knowledge not only helps with smooth operations but also saves you from costly repairs or unnecessary downtime.

Curious about how elevator wire ropes are configured? Let’s dive in and explore the common configurations and what makes them so important.

Rope configurations (or roping arrangements) refer to how the elevator wire ropes are wrapped around the sheave (pulley) to provide traction. They are essential in traction elevators, which use a counterweight and sheave system to lift and lower the elevator car.

Without the right configuration, the ropes cannot create enough friction with the sheave, leading to issues like slipping, uneven movement, and excessive wear. Different configurations are used based on building height, elevator speed, and load requirements.

Let’s look at the most popular rope configurations and how they are used in different scenarios:

This configuration is straightforward and typically used for low-rise elevators with moderate speed.

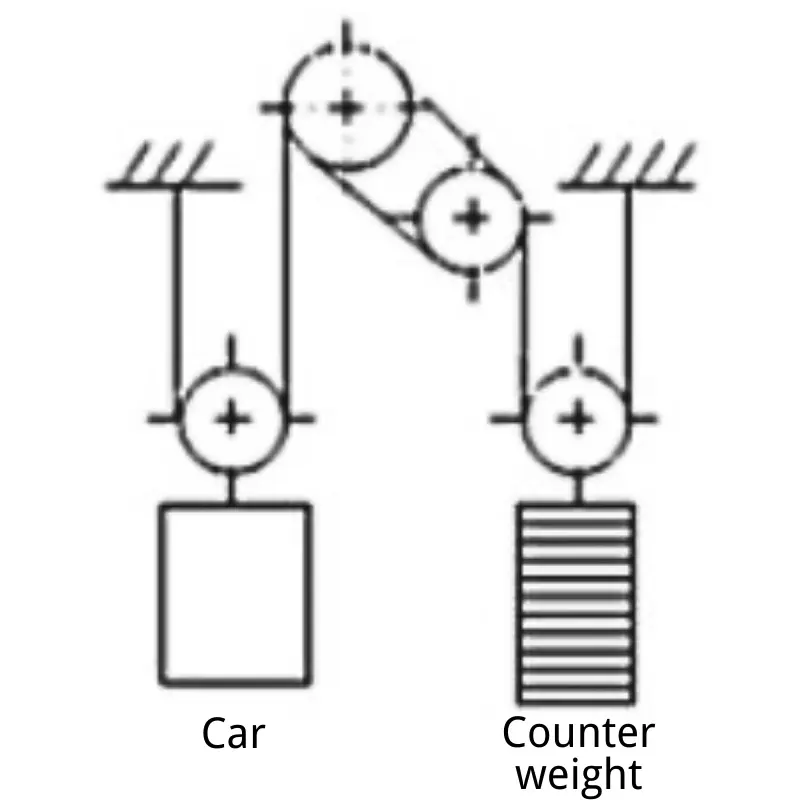

For high-speed applications in taller buildings, a single wrap isn’t enough. The double wrap provides additional traction by looping the ropes twice around the sheave.

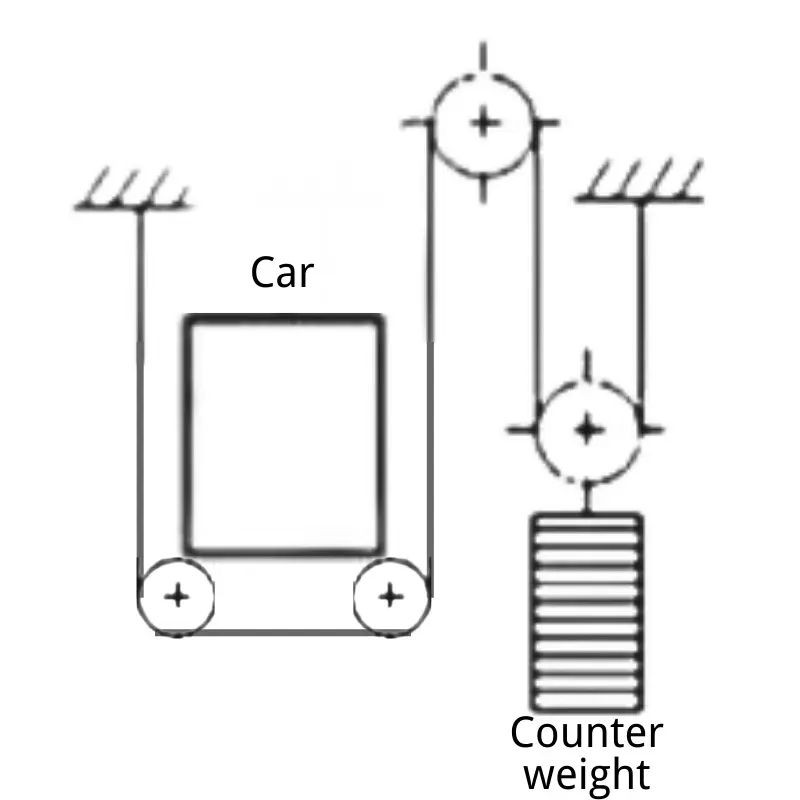

In this setup, the speed of the elevator car is half that of the ropes. This is common in machine-room-less elevators (MRLs).

This configuration doubles down on traction and is commonly found in high-speed, high-capacity elevators.

This configuration is a variation of the 2:1 single wrap but involves the ropes running underneath the elevator car. It’s commonly used in machine-room-less (MRL) applications and offers several advantages in terms of space and maintenance access.

How it works: The ropes are fed through sheaves located beneath the car, with additional sheaves attached to the car’s underside. This setup allows for vibration isolation and improved traction.

Best for: Machine-room-less elevators, where overhead space is limited.

Advantages:

To further enhance ride quality, vibration isolation pads are installed between the car sheave assembly and the elevator car. This minimizes the impact of rope and sheave movement on passengers.

Traction is what allows an elevator to move smoothly and safely. It’s determined by the friction between the elevator wire rope and the sheave. Poor traction can lead to slipping, reduced efficiency, and premature wear of components.

Here are the main factors that influence traction:

Low-rise buildings may only need a 1:1 single wrap, while high-rises often require 2:1 double wrap for greater traction.

Regular inspections are recommended every 3–6 months to identify wear or alignment issues.

Misalignment, poor sheave maintenance, and exceeding load capacity are common culprits.

In most cases, it’s better to replace ropes during reconfiguration to ensure safety and performance.

With proper maintenance, they can last 8–10 years, depending on usage and environmental factors.

Check the manufacturer’s specifications or consult your supplier.

Rope configurations are more than just a technical detail—they’re essential to the performance and safety of your elevator. Whether you’re dealing with a simple 1:1 single wrap or a complex 2:1 double wrap, understanding these setups can help you make smarter decisions about maintenance and upgrades.

At Potensi, we offer a wide range of elevator wire ropes and parts from trusted brands to suit every application. Contact us today for expert advice and top-quality products that keep your elevators running smoothly.

① Get 10% off on your first order.

② Get latest news about our promotion products.

③ Get our sales specialist VIP service 24/7.

④ Get access to our credit payment time.

WhatsApp us