Elevator air conditioners play a critical role in ensuring a comfortable ride for passengers while protecting sensitive elevator components and optimizing energy efficiency. As maintenance professionals, choosing the right replacement unit is essential to maintain system performance and reduce operational costs. In this article, we provide a comprehensive guide on the key considerations for replacing an elevator air conditioner, covering everything from capacity and energy efficiency to installation space and compatibility. Let’s explore the essential factors that will help you make an informed decision.

Before diving into selection criteria, it’s important to recognize when your elevator air conditioner needs replacing. Common indicators include:

Selecting the right air conditioner requires careful evaluation of several technical and environmental factors:

Assessment:

Calculate the required cooling capacity based on the elevator cabin’s size, insulation, and ambient climate. For buildings with significant temperature variations, consider a dual (cold and warm) unit that can provide both cooling and heating.

Type Selection:

In regions where heating is not required, a cooling-only unit may be more energy-efficient and cost-effective.

Efficiency Features:

Look for models that incorporate energy-saving technologies, such as inverter control, to optimize power consumption.

Long-Term Savings:

Consider the total cost of ownership by evaluating both the initial investment and the potential savings from reduced energy usage over time.

Electrical Requirements:

Verify that the new air conditioner’s voltage, current, and power ratings match the existing system specifications.

System Integration:

Ensure compatibility with the elevator’s control system, including communication protocols if using smart air conditioners (e.g., Modbus RTU or CANopen).

Material Quality:

Evaluate the build quality and materials used in the air conditioner to ensure it can withstand elevator shaft conditions such as vibration, dust, and temperature fluctuations.

Sealing and Protection:

Look for units with robust sealing to protect against environmental factors, especially in areas with high humidity or dust.

Standards Compliance:

Confirm that the air conditioner complies with relevant international standards (ISO, CE, UL) to ensure safety and reliability.

Additional Safety Features:

Prioritize units with built-in safety features, such as automatic shut-off and overheat protection, to further enhance system safety.

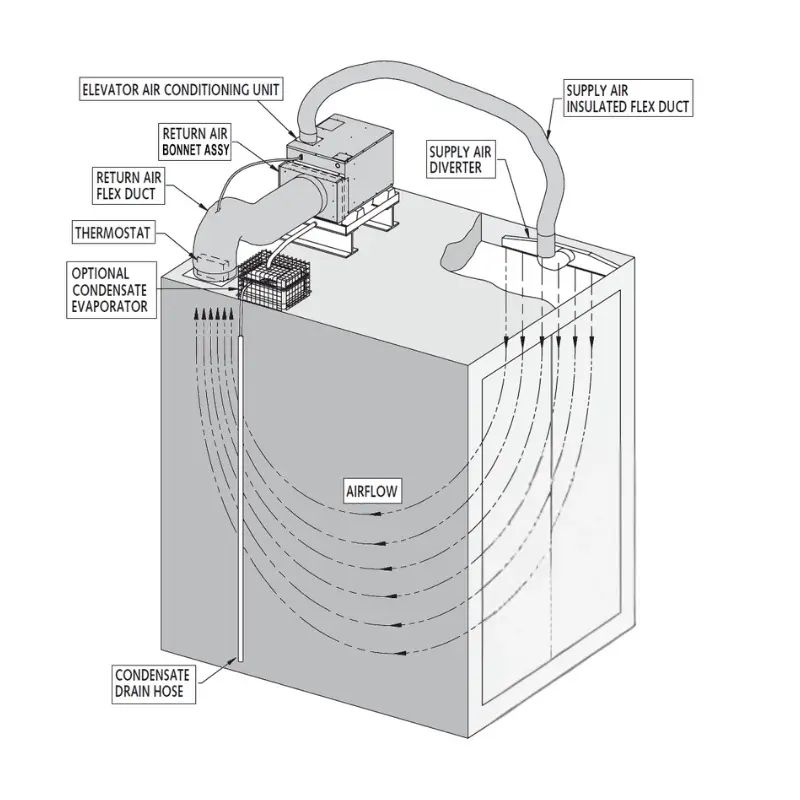

Proper installation and regular maintenance are crucial to ensure that your new elevator air conditioner operates at peak performance.

Avoid these common pitfalls when replacing an elevator air conditioner:

Choosing the right replacement parts is as important as selecting the right unit. High-quality elevator air conditioners ensure optimal performance, reduced maintenance costs, and long-term safety.

Replacing an elevator air conditioner involves careful consideration of multiple factors—cooling capacity, energy efficiency, compatibility, installation space, durability, and safety. By following best practices for installation and maintenance, we can ensure that our elevator systems remain efficient, safe, and cost-effective.

For reliable, high-performance elevator air conditioners and other essential elevator parts, we invite you to explore POTENSI premium product range. Our high-quality products and expert support are designed to meet the demanding needs of modern elevator systems.

① Get 10% off on your first order.

② Get latest news about our promotion products.

③ Get our sales specialist VIP service 24/7.

④ Get access to our credit payment time.

WhatsApp us