When an elevator shakes, even slightly, it doesn’t just make passengers uncomfortable—it raises important questions about safety and maintenance. As elevator component suppliers, we often hear questions like:

In this article, we’ll walk you through the common causes of elevator shaking, why it matters, and what to check when it happens. Whether you’re a building manager or a technician, this guide will help you better understand what’s going on behind the scenes.

Elevator shaking refers to noticeable movements—like vibrations, jerks, or small bumps—while the car is in motion or when it starts/stops. This may occur at certain speeds, on specific floors, or randomly.

Some shaking is minor and not dangerous. But in many cases, it’s a sign of wear, poor adjustments, or failing components that should be checked soon.

One of the most common reasons for shaking is poor alignment of the elevator’s guide rails or moving parts.

What to check: Guide rail straightness, secure bolts, and proper spacing top to bottom.

The steel wire ropes that pull the elevator car must carry the load evenly. If one rope is tighter than the others, it can throw the system off balance.

Signs of rope tension problems:

What to check: Rope diameter, stretch, and groove wear. In some cases, re-tensioning or replacing ropes may be needed.

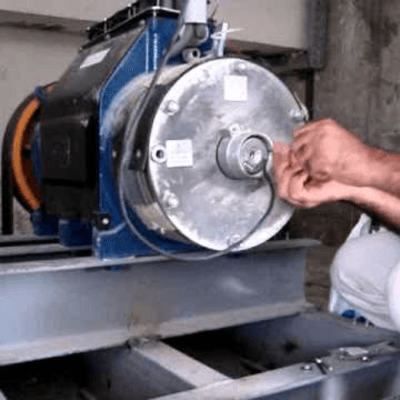

Bearings inside the elevator’s traction machine, guide rollers, or deflector sheaves can wear down with time.

What to check: Listen for unusual noise during operation and inspect moving parts for play or wear.

The elevator’s motor and brake system must operate smoothly.

What to check: Brake clearance, motor drive parameters, and startup torque settings.

Sometimes, elevator shaking is due to errors during installation or poor system tuning.

What to check: All mechanical connections, counterweight frames, and balancing settings.

Not always—but it depends on the cause. Minor shaking due to small misalignments or old ropes is often harmless but can lead to wear and tear over time.

However, shaking caused by braking issues, damaged components, or poor tension can affect the safe operation of the system. If ignored, this may increase the risk of shutdowns or more serious failures.

Here are some practical steps:

At Potensi, we understand how every small part affects the performance of your elevator. As a specialized supplier of elevator components, we offer a wide range of parts, including:

All our products are selected to ensure durability, safety, and compatibility across different elevator systems. We also provide technical support to help you choose the right parts for your situation.

If your elevator is shaking, don’t ignore it. Small vibrations can grow into bigger problems—and reduce rider comfort and system safety. By identifying the cause early and replacing worn parts, you can keep your elevator running smoothly and confidently.

Need help sourcing reliable parts?

Contact Potensi today to learn more about our elevator components and how we can support your maintenance needs.

① Get 10% off on your first order.

② Get latest news about our promotion products.

③ Get our sales specialist VIP service 24/7.

④ Get access to our credit payment time.

WhatsApp us