When we think about elevator safety, we usually focus on the ropes that lift the car or the brakes that stop it. But there’s another crucial part hiding in the pit: the compensation chain. This chain balances the weight of the power and control cables as the elevator moves. Over time, chains can wear, links can break, or guides can slip, leading to sudden slack or even derailment. That’s why secondary protection—a backup safety system for the chain—is so important. In this article, we’ll explain why adding this extra layer of protection matters for your elevators and how it keeps everyone safe.

First, let’s quickly review why elevators need a compensation chain:

Given their constant bending and exposure to pit conditions, compensation chains can wear, corrode, or even fracture a link over time.

When a primary chain link fails or a guide wheel slips, the chain can derail, creating dangerous slack or snagging cables. Effective secondary protection steps are needed to prevent a minor chain fault from turning into a major safety incident.

A single broken link can allow the chain to jump off its guide wheel. Without backup, that slack chain can:

Secondary protection—whether a backup loop, locking rings, or enclosed guides—catches the chain before it can derail, maintaining continuous tension and balance.

Compensation chains share dynamic load changes. If the primary chain loses tension:

With secondary protection in place, the backup mechanism immediately picks up load, keeping car and counterweight in harmony until trained personnel can address the issue.

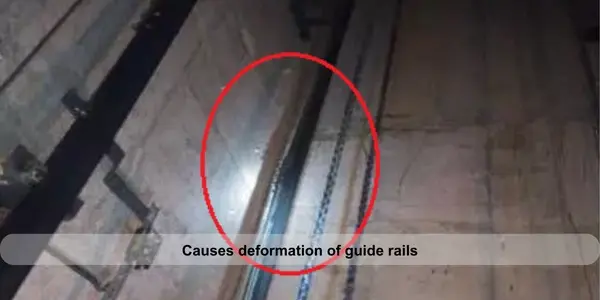

A derailed chain can run against pit walls or snag on machinery, leading to:

Secondary measures act as a safety net—preventing chains from escaping their intended path and damaging sensitive components.

There are three primary methods to back up the compensation chain:

A second chain runs parallel to the main chain, held slightly slack. If the primary chain fails, the backup loop immediately engages over the guide wheel, preserving chain tension.

Small metal rings clip around individual chain links. When a link fractures, the ring catches on the chain guide channel, stopping the chain from jumping off its track.

A rigid metal or polymer channel fully encloses the chain’s travel path. Even if a link breaks, the chain cannot move laterally out of the channel.

To maximize chain safety, we recommend the following best practices:

Secondary protection for elevator compensation chains is more than a recommendation—it’s essential for safety, reliability, and regulatory compliance. By adding a backup loop, locking rings, or enclosed guide, we:

As a professional supplier of elevator accessories, we encourage you to look at your compensation chain systems today. Contact POTENSI for high-quality secondary protection components and professional guidance. Together, we’ll keep your elevators running safely, smoothly, and confidently—ride after ride.

① Get 10% off on your first order.

② Get latest news about our promotion products.

③ Get our sales specialist VIP service 24/7.

④ Get access to our credit payment time.

WhatsApp us