Escalators are part of daily life in malls, airports, metro stations, and many other public places. They move people safely and smoothly. But like any machine, they can face problems. One of the most common issues is a derailed handrail. While it might seem minor, a derailed handrail can lead to serious safety risks if left unchecked.

In this article, we’ll walk through why handrails derail, how to identify the cause and the correct steps to fix them. Whether you’re an experienced technician or new to escalator maintenance, it’s important to follow the right process and use reliable parts.

Before fixing the problem, we need to understand what causes it. In most cases, derailment happens due to:

First things first—safety comes first. As soon as we notice a derailed handrail, we need to:

Never attempt to fix a moving escalator. Always ensure it’s completely shut down.

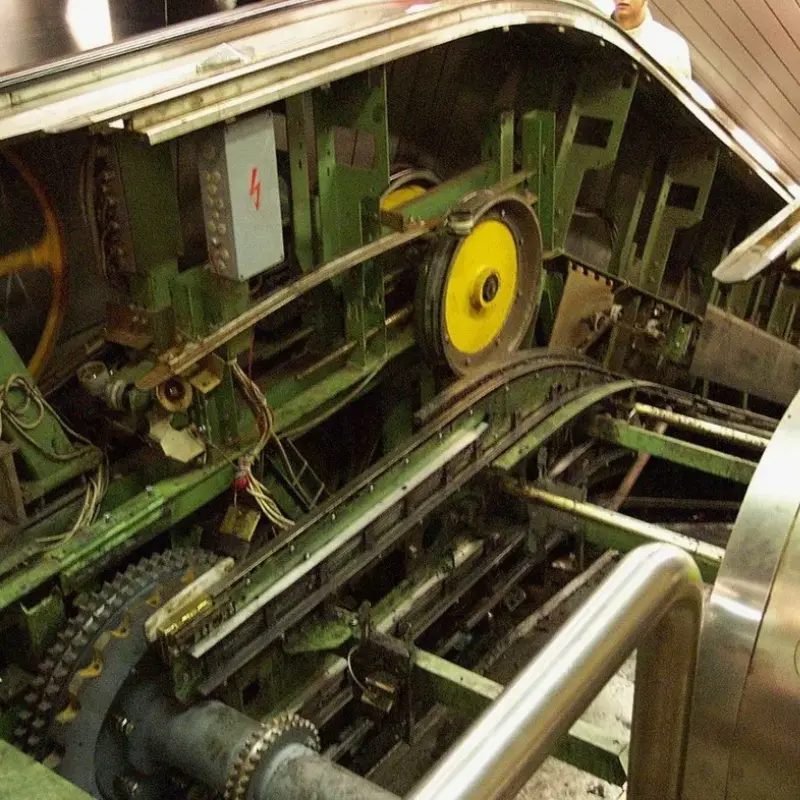

Now we begin a full inspection to locate the root cause of the derailment. We recommend checking the following:

Take your time. A proper diagnosis now can save hours later.

Depending on the condition of the handrail, we may either:

When installing a new handrail, it’s essential to:

A handrail that’s not centered or stretched evenly will derail again soon.

Don’t forget to inspect the handrail drive system:

If any components are beyond repair, replace them immediately. This is where high-quality spare parts come into play.

We recommend choosing trusted escalator parts suppliers like POTENSI, who offer durable, well-tested components specifically for handrail systems.

Once the repair is complete:

Let it run for a full cycle before putting it back into service. If anything feels off, stop and recheck.

Prevention is better than repair. Here are some things we’ve learned that help avoid handrail problems:

We also suggest keeping a spare handrail on-site for emergency replacement. This reduces downtime and avoids rush orders.

Fixing a derailed escalator handrail isn’t just about putting it back on the track. It’s about ensuring long-term safety and smooth operation. Every step—from diagnosis to re-tensioning and testing—matters.

When it comes to repairing or maintaining escalator handrails, using high-quality parts can make all the difference. At POTENSI, we supply a wide range of trusted escalator components that are built to perform under demanding conditions. Our escalator handrail are made from durable, wear-resistant materials that ensure smooth operation and long service life.

We also provide essential components such as step rollers, step chains, escalator clear machines, etc—all engineered for reliability and easy installation. Whether you’re replacing a damaged handrail or correcting derailment issues, you’ll find the right parts at POTENSI to get the job done safely and efficiently.

If you’re looking for dependable solutions and long-term support, explore our escalator parts catalog or contact our team directly. We’re here to help keep your systems running smoothly.

① Get 10% off on your first order.

② Get latest news about our promotion products.

③ Get our sales specialist VIP service 24/7.

④ Get access to our credit payment time.

WhatsApp us