Are you exploring elevator options for your building? If so, you’ve probably come across machine room (MR) elevators, one of the most trusted systems in the vertical transportation industry. But what makes them unique, and are they right for your needs? Choosing the wrong elevator could lead to increased maintenance costs, inefficiency, and unnecessary stress.

Machine room elevators are traction elevators that use a dedicated machine room to house key components like motors, controllers, and ropes. Known for their reliability, high capacity, and smooth operation, they remain a top choice for mid-to-high-rise buildings. In this guide, I’ll share everything you need to know about MR elevators and the essential parts that make them work seamlessly.

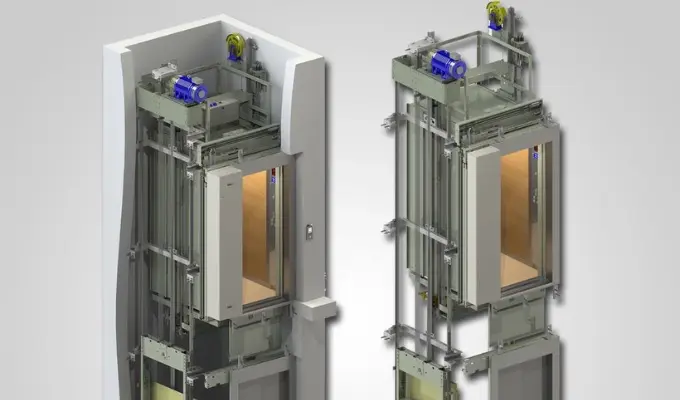

MR elevators are traditional traction elevators equipped with a separate machine room that houses critical mechanical and electrical components. The machine room is typically located above the shaft or in the basement, depending on the building’s design.

Understanding the key components of an MR elevator helps you appreciate its functionality:

MR elevators rely on a traction system that uses a motor and counterweights to lift and lower the cabin. Here’s how the process works:

This combination of parts creates an efficient, reliable, and safe transportation system.

Why are MR elevators still the go-to choice for many buildings? Here are their key advantages:

One of the main considerations for MR elevators is the need for a dedicated machine room. Depending on the building design, the room is located:

Tip: Ensure adequate ventilation in the machine room to maintain optimal performance for components like motors and controllers.

MR elevators are often compared to machine room-less (MRL) elevators. While both systems have their strengths, their differences are worth considering:

Modern MR elevators are equipped with advanced safety features, including:

These upgrades ensure compliance with the latest safety codes and enhance passenger confidence.

While MR elevators are not as inherently energy-efficient as MRL systems, several advancements can improve their performance:

Routine maintenance is crucial for MR elevators, but their separate machine room makes servicing easier. Key maintenance tasks include:

Proactive maintenance can extend the lifespan of components and prevent costly breakdowns.

MR elevators may involve higher upfront costs due to the construction of a machine room and robust components. However, their long lifespan and reliability offer excellent value in the long run.

High-rise commercial and residential buildings with heavy traffic are ideal for MR elevators.

Regular servicing every 3–6 months is recommended for optimal performance.

Yes, upgrading parts like motors, controllers, and safety devices can improve efficiency and compliance.

MR elevators are a proven choice for reliable, high-capacity vertical transportation. Their robust design, smooth operation, and compatibility with modern components make them an excellent investment for mid-to-high-rise buildings.

At Potensi, we supply top-quality elevator parts, including traction machines, control panels, light curtains, and safety systems. Contact us today to upgrade your MR elevator and enhance its performance for years to come.

① Get 10% off on your first order.

② Get latest news about our promotion products.

③ Get our sales specialist VIP service 24/7.

④ Get access to our credit payment time.

WhatsApp us